Automotive industry

Bar turning and machining parts for the automotive sector

We produce innovative components for the automotive industry.

Our comprehensive knowledge of the industrial processes of automotive OEMs allows us to accompany our customers in the success of their projects.

Operating in the automotive industry for more than 40 years, our expertise allows us to provide you with the manufacture of machined parts in medium, large and mass production runs.

Certified IATF 16949, ISO 14001 and ISO 9001, we are able to meet the most demanding specifications.

We manufacture bar turned and machined parts for various applications such as:

- ABS braking systems

- Connectors

- Fastening

- Temperature sensors

- Pressure sensors

- Position sensors

- Hydraulic circuitry

- Actuators

- Ignition system, ignition plug bodies

- Connectors

- Batteries for hybrid and electric vehicles

- Air conditioning

Examples of components machined in our workshops:

- Anker,

- Framework,

- Axes,

- Rings,

- Tappets,

- Inserts,

- Connector bodies,

- Valves,

- Jackscrews,

- Washer,

- Pistons,

- Fittings,

- Plunger,

- Hubs,

- Tassels,

- Fitting,

- Actuators,

- Spacer,

- Housing,

- Baseplate,

- Male connectors,

- Female connectors,

- Ignition plug bodies, …

Our organization and machinery allow us to work with medium and mass production for the automotive industry, generally from 500,000 to 10 million units.

Our machinery for the automotive industry

We possess traditional multispindle machines suitable for mass production and numerically controlled multispindle machines for maximum productivity and complex machining.

Materials machined in the automotive industry

STEEL

S235JRC (1.0122 / A37 / E24 / ST37)

S355J2C (1.0579 / E36 / ST52)

C45 (1.0503 / XC48 / C45)

Steels for quenching and tempering

C35R (1.1180 / XC38 / C35)

42CrMoS4 (1.7227/42CD4/42CrMoS4)

Steels for case hardening

16MnCrS5 (1.7139 / 16MC5 /16MnCr5)

20MnCrS5 (1.7149 / 20MC5 / 20MnCr5)

Free-cutting steels hardened

36SMn14 (1.0764 / 35MF6 / 35S20

44SMn28 (1.0762 / 45MF6.3 / 45S20)

11SmNPb 30 / 37

Pre-treated steel

42CrMo+QT (1.7227)

18CrMo4

x30Cr13+QT (1.44028 / Z33C13 / 420B)

Lead-free steel

Stainless Steel

X6Cr17 / 1.4016

X14CrMoS17 / 1.4104

X6CrMoS17 / 1.4105

Martensitic

X4CrNiMo16-5-1 / 1.4418

X5CrNiCuNb17-4 / 1.4542

X12CrS13 / 1.4005

X20Cr13 / 1.4021

X30Cr13 / 1.4028

X29CrS13 / 1.4029

Austenitic

X8CrNiS18-9 / 1.4305

X2CrNiMo17-12-2 / 1.4404

X6CrNiCu18-9-2 / 1.4570

X2CrNi18-9 / 1.4307

Brass and lead free brass

CuZn36Pb3 / CW603N

CuZn38Pb2 / CW608N

CuZn39Pb2 / CW612N

CuZn39Pb3 / CW614N

CuZn42 / CW510L

CuZn21Si3P / CW724R

(Non-exhaustive list)

Aluminium parts

Quality management at IVALTECH

- 3D scanner,

- Keyence,

- Contour measuring machine,

- Roundtest,

- Tesa-scan,

- SPC monitoring,

- Cleanliness measuring in a dedicated laboratory (gravimetry and granulometry)

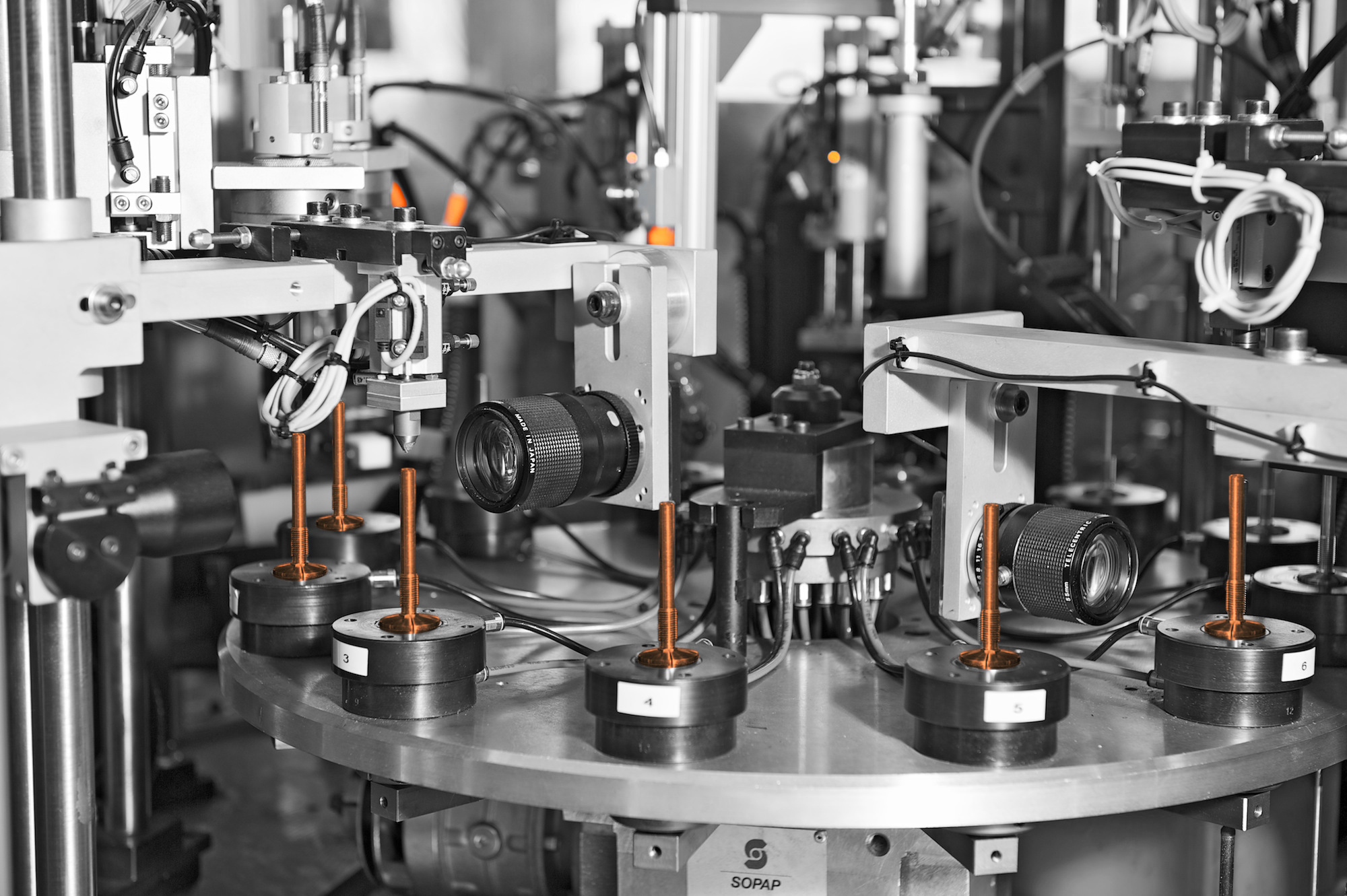

100% automated inspections

To guarantee zero defects, we are equipped with 100% automated inspection equipment for components in medium and mass production.

Additional operations

Via our stringently selected local partners, we can also offer you various finishing operations such as

- Surface treatment,

- Heat treatment,

- Thread and immersion rectification,

- Honing,

- Microfinishing (sandblasting, polishing, deburring),

- Unitary storage of your parts, vacuum sealed packaging …